…well it feels that we are closing in on the finish line. No doubt there will be more issues to resolve once the finish line has been passed.

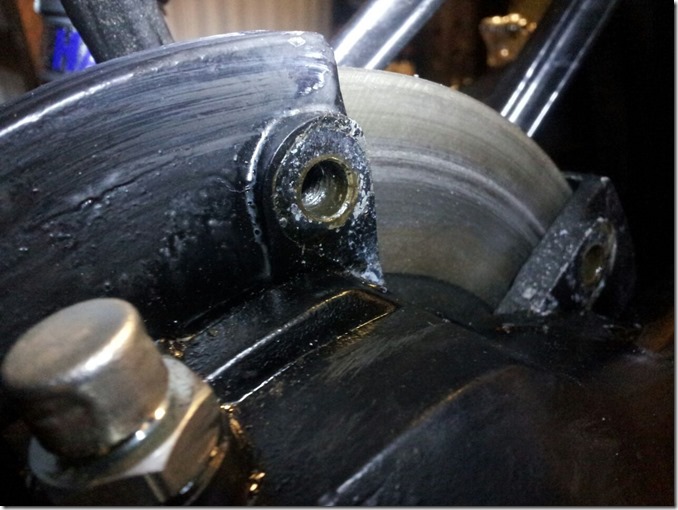

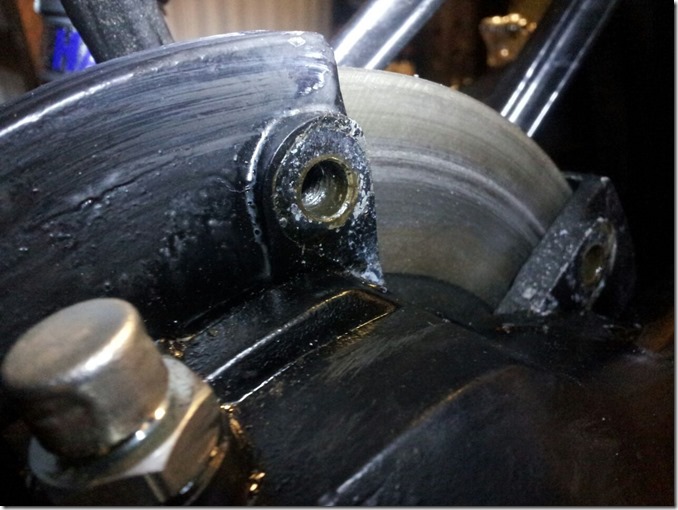

The first issue that came to light once a 50m test ride showed was that something was holding the bike back. This was traced to an everso slightly too long pair of bolts holding the rear brake caliper on…might have been my fault that…picking up the wrong bolts. The disc has been slightly scored as a result but nothing major that will impact upon the braking operation.

As can be seen from the photo above some bits of paint are going to need touching up where brake fluid has got on it whilst bleeding them.

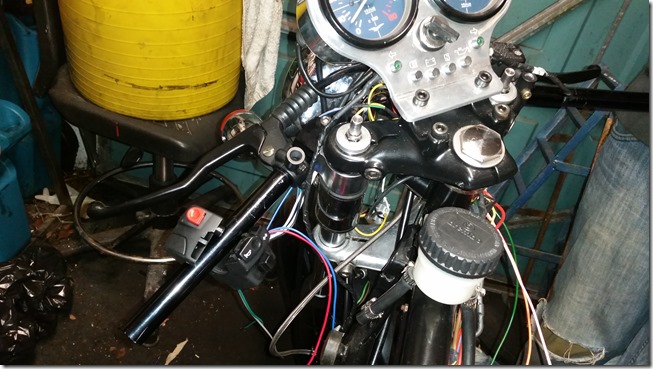

As can be seen from this photo below the brake calipers are in my ideal position behind the fork legs, simply aesthetics. However, reversing them to this position has the unintended effect of making the speedo needle try and run backwards. Also, as I didn’t get the tyre taken off and reversed the correct rotation direction is now back to front. I could have spent an age looking for an anti-clockwise speed drive and taken the tyre off and turn it around, but it was easier to put the fork legs back as they were from the factory.

The white residue that can be seen on the wheel and mudguard is from using brake cleaner to remove brake fluid…it will all tidy up by the end.

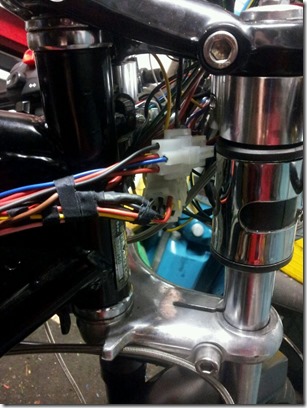

The process of removing the front wheel, whipping the forks out and bleeding the brakes was surprisingly straight forward. The brake lines will be clamped to the forks with p-clips to tidy it up.

Considering how useful the centre stand is I am thinking that although it keeps quite a bit of weight on the bike I may keep it on permanently…not sure yet, but whilst debating the pros and cons I thought I would put another spring on it…not a lot of skill required.

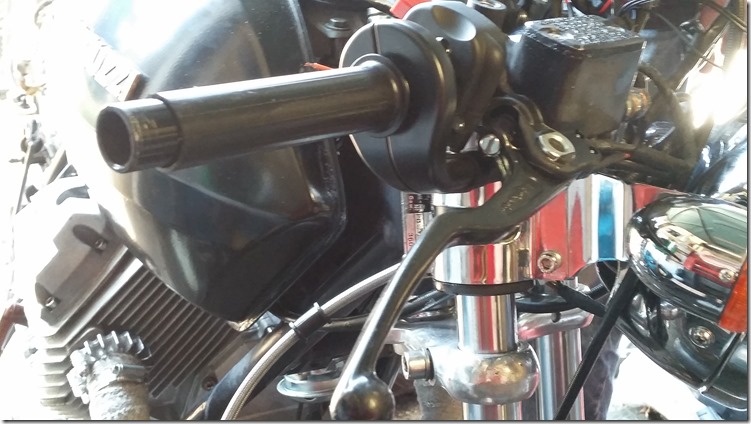

After a little tweaking we now have a working throttle assembly from a Honda 250 crosser.

…and whilst balancing the carbs the throttle is working perfectly.

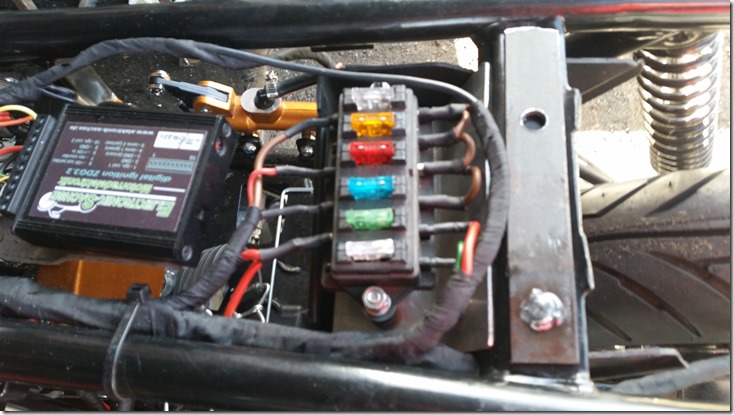

Once the brakes had been filled with fluid and bled using the back bleeding method with a syringe on the caliper bleed nipple the front brake lever still travelled too far back to the bar. As the span adjuster screw was in as far as it would go it was decided that the actuating rod that enters the master cylinder could do with being longer. So a slim bolt was cut down and shaped and has firmed up the lever with enough travel to work the front brakes without going back to the bar.

With a little stutter we tried the Little Goose up the road…in the second clip you can see flame coming from the nearside (left) exhaust silencer….hmmm…unburnt fuel for some reason?

Can’t beat a misfire late at night! Consideration is being given to the float possibly sticking in the left carburettor as the left hand cylinder and exhaust silencer were both barely warm compared to the other side which was as hot as you might expect. So a clean of the carb is on the cards…again.

Next time more fabrication on the seat, fit grips to the bars and pop a bar end mirror on…then we might be ready for the MOT once she runs right.